Three unique behaviors differentiate a Quality leader in the pharmaceutical industry from leaders in other industries.

- The ability to motivate and engage employees in a highly regulated environment.

- The approach you take to making decisions as they might impact the health of patients.

- How you articulate the importance of quality and cGMP compliance to the C-suite in a business context

This article discusses each of these three behaviors based on our combined several decades of experience as Quality leaders.

The Good Manufacturing Practice (GMP) legal framework outlines the responsibilities of the Quality department and the Head of Quality. Although senior management of the company has the ultimate responsibility for ensuring that an effective pharmaceutical quality system (PQS) is in place, it is in practice the Head of Quality who is management’s representative in all key matters related to quality and compliance and thus establishes and operates the PQS. The Head of Quality (or the Qualified Person in the EU) decides whether each drug product batch produced is released or rejected, and he/she also decides on the outcome of all quality related investigations. If the company has a culture of transparency and compliance the job is much easier than if the opposite is the case. In the latter case the Head of Quality can feel the responsibility as ‘carrying the weight of the world’ on his/her shoulders. Under these conditions ensuring compliance is not guaranteed. The best situation is when everyone involved in GMP activities feel the same ownership for quality and compliance as the Head of Quality, regardless of their position within the organization. So how do you motivate and engage people in quality?

Motivation

The first task is to connect every employee to the purpose of the company, which ultimately is related to improving public health when you work in the pharmaceutical industry. It can be preventing diseases by supplying vaccines, curing or treating diseases by providing drug products, providing vials or syringes for drug products, etc. Establishing a connection between the purpose and the daily activities of each employee is not as trivial as one would think. It has to be done in a way that makes sense to the individual, and in a way that he/she takes to heart and thinks about every day. You want to engage both the head and heart of every employee. We had a situation once where an employee didn’t follow the established procedures for gowning and caused a sterility failure when testing several product batches. Although we were quite sure that the sterility failure was caused by the person doing the test rather than the product not being sterile, we had no choice but to reject all the batches tested. As a result, there was an immediate stock out and drug shortage. The employee was very proud of working for the company and knew the purpose statement very well. However, it took a conversation with the employee about how his action likely caused a drug shortage and thus adversely affected the well-being of patients to clearly connect his actions with the patients’ welfare. The more one can have each employee think about the purpose of the company in every action they take the better it is.

Another recent example is the error at a contract drug manufacturer where two different corona virus vaccines were being manufactured. Production operators unfortunately mixed-up ingredients from the two vaccines resulting in the contamination of 15 million doses of vaccine. This error resulted in a delay in the authorization of the plant’s production lines, failure to provide much needed vaccine doses to the public in the midst of the pandemic, and substantial financial loss. Furthermore, an error such as this can result in difficult-to-repair damage to a company’s reputation in direct contrast to the company’s mission. Once again, if the operators’ role and the purpose of the company were more strongly linked, this error may not have occurred. This example also shows the importance of motivated employees as it takes everyone to make a batch successfully, and only one to cause the batch to fail.

It is important to have these types of conversations to connect actions with purpose. How you do this is extremely important. If you have a culture of fear of failure what often happens is that employees try to hide mistakes, blame others or simply don’t do their best every day. That’s a very dangerous culture from a safety and compliance perspective, and certainly one that makes the job of Head of Quality very challenging. If you on the other hand have a culture where employees feel psychologically safe to speak up, and you use these types of errors as a learning opportunity to avoid the situation happening again you are on the right track.

Recently Amy C. Edmondson wrote about her research into creating psychological safety in the workplace in her book “The Fearless Organization”. An environment of psychological safety promotes shared expectation and meaning, confidence that speaking up is welcomed, and an orientation towards continuous learning. As Quality leaders we must be clear about the direction we are going and communicate it to all in the company. How we are getting there should allow for flexibility and inclusion of everyone’s ideas. We must also make it clear that compliance is mandatory for all, not an option, and demonstrate there are consequences if people don’t live up to this. As leaders we must ‘walk-the-talk’ when it comes to compliance, not take any shortcuts, and speak up if anyone advocates or acts differently – no matter their position in the company. Depending on one’s role in the organization, each will have a different priority. For example, manufacturing lots of product according to a production schedule, or keeping the shareholders happy. Nevertheless, patient safety should always be foremost in everyone’s mind.

John Kotter and his team have studied brain science and linked it to why some organizations are successful while others are not. They have summarized their most recent work in a new book “Change” that is coming out this summer. Their study includes what they call the survive/thrive system and how these two channels are hardwired into how we act. The survive channel sees change and challenges as a threat, and we have certain ways of acting which includes fear and anxiety. The thrive channel on the other hand sees opportunity and acts with passion and excitement. As Quality Leaders it is very important that we find a good balance between the two channels, create a psychological safe environment, and don’t shut down people’s innovation and ideas. We want an environment of “see something, say something, do something” to continually improve compliance. It is our view that if you focus on quality ownership by all, compliance will automatically follow.

We all know that when we do things because we want to, we engage with more energy than when we do things because we have to. Just think about your energy-level when you spend time on one of your hobbies versus when you have to complete a chore. When we bring more ‘want to’ into the workplace as it relates to quality and compliance, we have a much better chance of everyone owning quality. Some of you might think “well that’s all good but all we do in the pharmaceutical industry is following very detailed standard operating procedures (SOPs) explaining in excruciating detail every step and action we must follow when we manufacture and test a batch of drug product”. And yes, we can’t have our employees ‘fine-tune’ and change the production process from batch to batch as they see fit. We want our manufacturing variation to be as small as possible. However, there is a risk that people ‘switch their mind off’ and just follow the checklist. We want every person to be alert, observe and bring forward ideas and improvements. Creating such space is an important task for the Quality leader. As W.E. Deming said more than 35 years ago as one of his 14 points of management “the aim of supervision should be to help people do a better job, remove controls and bureaucracy”. Remember that it takes everyone to make a successful batch. So as Quality leaders we must balance strict adherence to SOPs and procedures and help people to do a better job. When changes are suggested they should be assessed through the company’s PQS and implemented to continually improve our processes and reduce batch-to-batch variation.

One approach that we have found particularly effective is to create a culture where all members of the organization feel that they own quality. A concept related to this was developed by John Kotter and his team and is described in several books including the best seller “Accelerate”. It builds on an eight-step process utilizing ‘accelerators’, and four change principles which we have already mentioned, ‘want to’ versus ‘have to’, ‘head and heart, not just head’, ‘more leadership and management, not just management’, and ‘many change agents, not just a few appointees. It involves the co-creation of an opportunity statement that describes what, why, why us, why now and why bother about change to a desired state. It should also connect to the purpose of the company. We have applied the approach both in small as well as large multi-site and global companies. The cultural transformation we have seen is amazing and so are the business results and improved quality mindset and compliance. People from all parts of the company find new ways of connecting and develop wins, results that make today better than yesterday and tomorrow better than today. It is important to appreciate that everyone can be a leader and leadership doesn’t equate to being a manager in the organizational hierarchy but can come from anyone anywhere in the organization. Quality culture has been and continues to be a topic of high interest and importance, and certainly you need the right culture to engage all in quality and compliance. One of the key learnings for us is that creating and maintaining the desired culture requires certain competencies and skillsets just as it does to produce and test a batch of drug product or maintain the equipment. Appreciating this is important for implementing a successful culture.

We often think about our leadership in terms of whether we are a roadblock or a facilitator. In a previous job there was a lot of escalation to senior management. There were even meetings called ‘escalation meetings’. We talked about it and agreed that every time we heard the word escalate, we would stop and discuss how we could equip our employees better to make decisions at the lowest level possible in the organization. Motivation is important and so is the ability to do a job. Motivation and ability are both important to achieve results. Grenny, et.al. wrote about that in their book “Influencer” at the personal, social and structural level. The book is in our view particularly relevant and useful when you lead work in an organization where you don’t have direct line responsibility. That is usually the case for Quality leaders as we are responsible for compliance, and yet most of the work covered by the cGMPs are performed by people outside the Quality organization (manufacturing, technical services, etc.)

As just stated, motivating people is not enough. It is important to select the best candidates for each position taking into account experience, knowledge and fit within the organization. Employees from shopfloor technician to the Head of Manufacturing should be enabled to learn new things on the job. In this way, they enrich their worklife, add to their skillsets, and increase their contributions to the success of the company. Promotions should be encouraged from within to provide additional motivation for the staff. Sometimes we have experienced and motivated employees wanting to do a good job, but they simply don’t have the ability to do so. Helping them through new ways of connecting with their co-workers, removing roadblocks and providing training is extremely important. Every employee should have a training plan that will take them on the path to proficiency. While many organizations have employees read SOPs only, we have found on-the-job-training to be much more effective in achieving competency.

One thing that can never be overemphasized is the importance of recognition for a job well done. It doesn’t have to be formal and once a year in a performance review. There are so many ways of recognizing people – and it should preferably be timely, ‘in the moment’. Sometimes simply saying thank you works, other times it can be financial, in some cases awards or other forms of recognition are effective. In one company recognition was rewarded with tickets to a professional sporting event. It is important to celebrate successes. David Novak wrote the book “O Great One” which is all about different ways of recognizing people. He has summarized it in 10 principles the first one being “People won’t care about you if you don’t care about them”.

Decision making

“What is the right thing to do for patients?” Answering this simple question has helped us throughout our careers as Quality leaders in many decisions we make. Sometimes you must make a final call on whether a deviation is so serious that a batch must be rejected, a raw material cannot be used, a test result is invalidated, or in extreme situations you gain new knowledge which suggests you must recall a batch already on the market. Some decisions can cause a supply shortage as we mentioned earlier in this article. Some can have a big financial impact for the company. In many cases different stakeholders within the company may have different views on what the decision should be. Sometimes you feel pressure from certain groups or individuals to make a rapid decision. It is very difficult to stand one’s ground when individuals at the highest levels of the organization disagree with your decision. However, if you always keep the patient’s safety in mind you cannot go wrong. The reality is that most situations are rarely black or white but almost always somewhere in between. With experience you become better at making decisions. So, what is the right approach to making decisions as a Quality leader knowing that your decisions can have significant impact?

One thing that works no matter which type of decision you face is to arrive at a conclusion in an informed way. By that we mean gather facts and data, listen to the views of experts and those closest to the issue, make sure that those who have an opinion that is likely different from yours are invited to participate in the decision-making process and that their opinions are considered. It is easy to be biased and listen for things that you want to hear. Dan & Chip Heath wrote about this in their book “Decisive” and describe various techniques you can apply both at work and in life in general.

We have experienced more than once that a problem that warrants an ‘unpopular’ decision ends up on the Quality leader’s desk rather than where the issue arose. As an example, ‘everyone’ can see that a batch should be rejected but leaves it to Quality to reach that conclusion. Quality then becomes the ‘messenger of bad news’. Rather than flat out saying “the batch must be rejected” we have good experience with asking the question “what do you think is the right thing to do for patients?” or simply asking “What would you do if you were in my shoes?” Asking questions like that often takes out the tension and aligns everybody with the right decision.

Once a decision is made it is important not only to communicate what that decision is, but also explain the rationale for getting to that particular decision. This includes how you evaluated facts and different views, considerations of benefit to patients and compliance, and other relevant factors. We see this communication part of the decision-making process as also being important when you try to establish the desired quality culture and engage people. If everyone understands the principles and the thinking behind making the right quality decisions over time, more and more decisions will be made at lower levels in the organization and in many cases, issues will be solved before they end up on Quality’s desk.

One element of decision making that is particularly challenging and yet very important is what we call a risk benefit assessment. Let’s say that you identify a cGMP compliance issue, and it can be debated if it is significant enough to reject a batch. You know that there is no safety risk to the patients but at the same time you are not fully compliant. You also know that if you reject the batch there will be an immediate stock out and the drug shortage can result in patients getting sicker or even dying. What would you do? What’s your decision? It really depends on the situation, and either way you need to justify your decision. We feel that over the past several years we have become completely compliance focused to the extent that we have lost patient focus. For example, an injectable product which is medically necessary has a pH specification of 6.2 – 6.9. The product is in short supply and the lot in question has a pH of 7.0. All other parameters are within specification. The lot does not comply with the pH specification. However, a written medical opinion has been obtained attesting that the lot is safe for use in patients. Do we reject the lot because it is out of specification for pH, or do we consider patient safety and patient need? In our view we must find a healthy balance of realizing benefits to patients and at the same time manage risks. Being only focused on compliance has the benefit of discipline, controls, reliability, rules, standards and order. However, it can also lead to check-the-box mentality, bureaucracy, complacency, blind compliance and mistrust. When you are more patient focused you are more behavior driven. You ensure safe, efficacious quality drugs are supplied by making good judgment calls, welcoming change and trusting people. However, when the pendulum swings too much in this direction it can lead to confusion, added risks, mistakes and ultimately chaos. As a Quality leader you need to find the right balance. So, what do you do if you release a batch to the market to avoid patients getting sicker or dying because of potential drug shortage, but also know you have a minor compliance issue? First, you call the local regulatory agency where the drug product is intended to be released and discuss the issue with them. Second, you discuss/communicate the weighing of availability of the drug product to patient vs the compliance issue with employees in the company, emphasizing that this is not a preferable situation to be in. Thirdly, you initiate CAPA(s) to fix the compliance issue and make sure that everyone in the company prioritizes their implementation.

The C-Suite

The Quality thought leader Joseph M. Juran once said “It is most important that top management be quality-minded. In the absence of sincere manifestation at the top, little will happen below”. This is true. The single most important factor to create (or destroy) a quality culture and an environment where everyone demonstrates that they own quality is the CEO (or Executive Committee). We have experienced both situations. Although you as a Quality leader are driving the compliance and quality agenda you have to have the full support from the CEO and the Executive Committee. This requires that you are able to explain the importance of both in terms that are different from the usual ‘cGMP lingo’. And you need to have a clear communication strategy that details how and when the CEO communicates quality related topics. The HR performance system must reward individuals and teams that demonstrate the right quality behavior.

W. E. Deming said in one of his 14 Points of Management “Improve quality and decreased cost will follow”. There is no doubt that this is true. Doing things right the first time will always be the cheapest way in the long run. However, countless times we have seen cost reduction initiatives where quality suffers and leads to increased cost in the longer run. So why is this the case? One reason is that prevention of risks through quality improvements is a budget item or in other words money you decide to spend. Cost of failures on the other hand is often not budgeted upfront and becomes a P&L item. The Quality leader has a role to play in this regard. We need to be able to articulate not only the cost of prevention (risk mitigation) but also the cost of failure and the likelihood or risk of it happening. The C-Suite needs to hear the business context of quality related matters.

The Quality System, the IT structure, and the Quality Plan are excellent places to apply quality improvement initiatives. Think about them not only in terms of reduced number of deviations but also in terms of improved reliability of supply and cost reduction once the improvements have been achieved. As Quality leaders we must be able to adjust our language (not the message) to whom we are talking with.

A Quality leader must be bold when speaking with the C-Suite on issues of quality, safety and compliance, by bringing up these issues as soon as they are known and providing suitable solutions to protect the end users. While the C-Suite have a responsibility to shareholders, employees and the financial success of the company, they also have a moral responsibility for the well-being of patients who use their products.

We often build ‘clutter’ or bureaucracy over time. It is important for the Quality leader to look for simplification on a regular basis. Increased complexity doesn’t equate to increased compliance. Often systems tend to digress from what used to be simple and one-size fits all, to more customized and complex systems. Believe us, it doesn’t matter if your Change Control or Deviation Management system have 2, 3 or 4 layers of increasing importance. But it does matter if you have more than one system in the company. The same goes for IT systems. You really only need one LIMS system, and one document management system. Any more than that is confusing and a waste of money.

For the CEO to be supportive of the desired quality culture and to foster an environment of compliance and quality owned by all it is important that she/he is aware of both plans, and when the company faces issues that might impact the business. Timely communication of potential or realized issues, with context and plans for remediation is very important.

Someone at some point said, “It is best when the CEO doesn’t know much about quality and the Quality organization, because that means things are going well”. We disagree with that statement. It is important that the CEO and the Quality Head know each other well, that the Quality Head is supported in actions from the CEO, that the CEO is well informed about and involved in what is going on in compliance and quality wise in the company, and that the Quality Head plays an active role in running the overall business of the company.

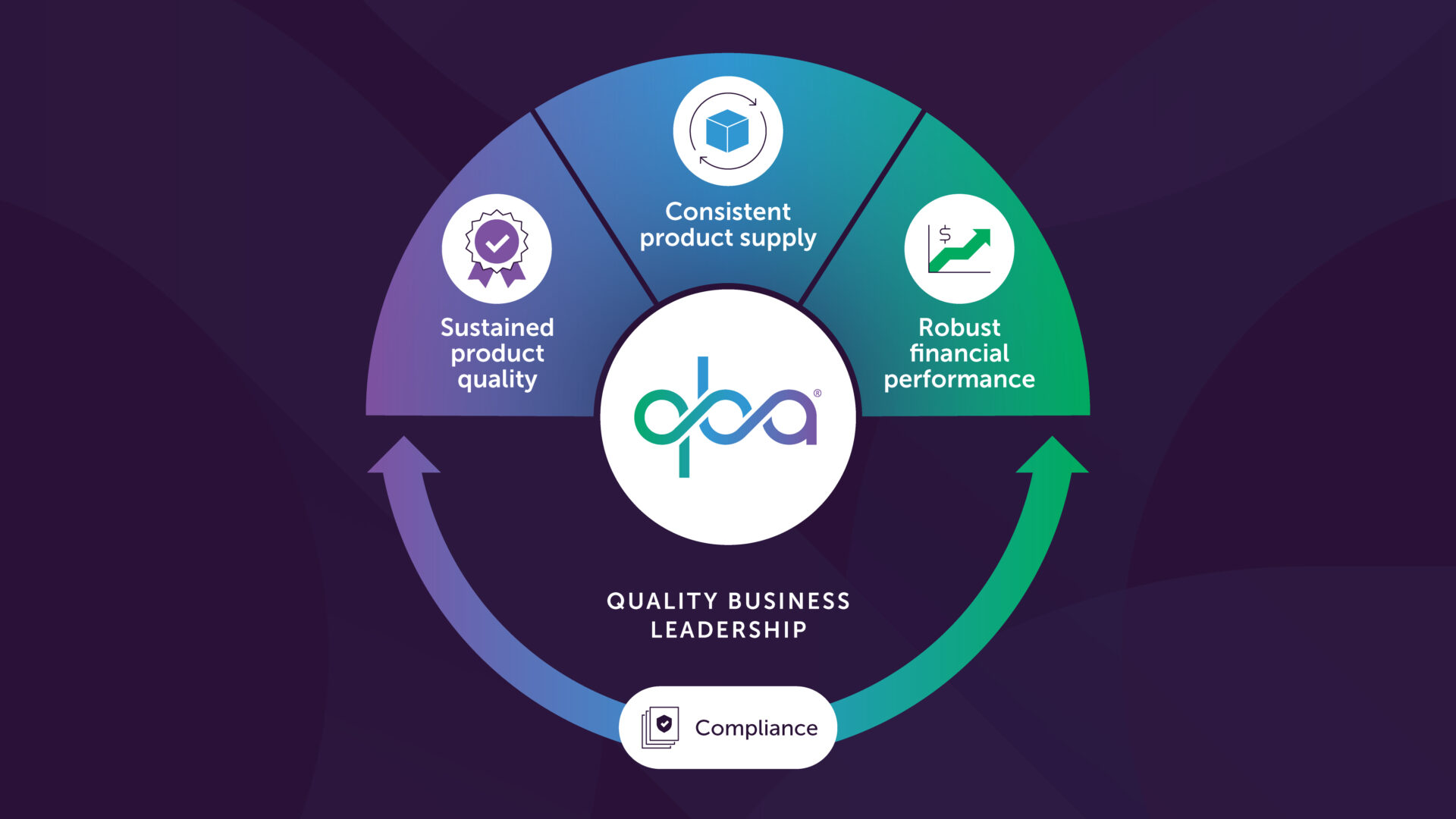

In conclusion, the role of a Quality leader is unique in that he/she must establish and maintain quality and compliance standards for the company, motivate employees, and make difficult patient safety decisions, while at the same time supporting the business goals of the company. This is a difficult balancing act. However, by always keeping patient safety in mind, the Quality leader will make decisions that are best for both the patient and the company.

References

- Amy C. Edmondson, “The Fearless Organization”, Wiley

- John Kotter, et.al., “Change”, Wiley

- W.E. Deming, “Out of the Crisis”, The MIT Press

- W.E. Deming, “The New Economics”, The MIT Press

- John Kotter, “Accelerate”, Harvard Business Review Press

- Grenny, et.al., “Influencer”, McGraw Hill

- David Novak, “O Great One, Portfolio/Penguin

- Chip & Dan Heath, “Decisive”, Currency

Anders Vinther and Lee Carpe have a 30+ and 50+ years’ experience respectively as quality experts and leaders from small as well as large multi-national companies in the pharmaceutical industry.